How can smarter quality testing both ensure patient safety and improve operational efficiency?

Unlock the potential of in-process monitoring

Quality monitoring is about more than just being compliant. Delivering high-quality products requires a well-designed quality system; and adding in-process checks at strategic points provides valuable data that act as green and red flags throughout the production process. These data give assurance your process is working as designed and confidence your products will pass all release tests.

Drawing on over 55 years of microbiological testing expertise, bioMérieux offers a consultative approach to help you add key in-process controls as part of a smart testing strategy designed to enhance your operational excellence.

From quality control to operational efficiency

As operational managers, you know that having the right information at the right time makes all of the difference in triggering early interventions to address issues when they arise to mitigate adverse results.

For example, rapid test results make it possible to achieve a risk-free, same-day restart of your water loop, avoiding major downtime of your production process by reducing the time required to investigate root cause. Perhaps more importantly, rapid quality results can prevent a costly 3 to 4-day period of production that is contaminated which not only saves money but also helps you regain valuable production time.

Tailored solutions & services for every specialty

Do you run a bioproduction facility? We understand that you need maximize yield of your drug substance while completing all required documentation on time with no safety issues and at the best cost. Whether you are looking to find ways to increase efficiency of your upstream process or ensure a secured downstream process, bioMérieux can work with you to find solutions.

Developing cell and gene therapies presents its own challenges; low-production volume, short shelf life, temperature sensitivity, complex raw materials, tracking and data integrity, scalability, and patient demands must all be taken into consideration. Our rapid and automated quality control tests supply the objective and automated data you need, when you need it, close to the production floor, to quickly release your cell and gene therapies.

Diagnostics solutions and comprehensive support

bioMérieux provides a full range of diagnostics solutions for all your microbiological quality testing needs. Our solutions also include premium services, from feasibility to validation, to ensure a quick return on investment.

HOW WE CAN BRING VALUE TO YOUR PRODUCTION PROCESS?

Find out how we help improve your operational performance while ensuring quality production for your customers and the patients.

Implementing tools that provide rapid results reduce the cost of non-quality by cutting direct and indirect costs from scrap, investigations, downtime, decontamination and additional human resources. All of these reductions increase operational efficiency and ultimately improve your production yields.

Your solutions:

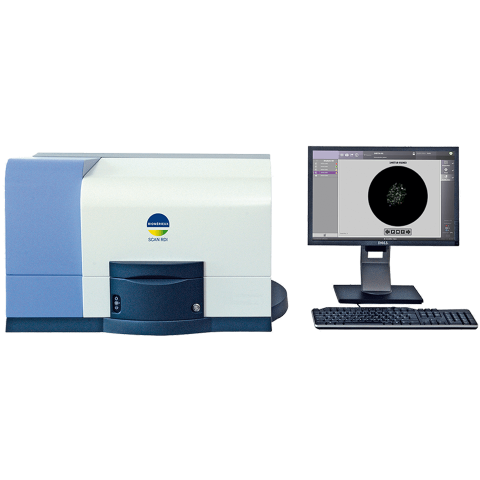

SCANRDI® (results in 3 hours), BACT/ALERT® 3D and BIOFIRE® Mycoplasma (results in less than 1 hour) for fast results, ease-of-use and data integrity provided by automated systems.

Strategic quality testing helps preserve your production slots and deliver more manufactured units to reach or exceed your yearly targets. Smarter quality testing can also Improve your balance sheets by optimizing inventory, reducing warehousing costs of quarantined goods and maximizing your cash flow by releasing products sooner.

Your solutions:

SCANRDI® (results in 3 hours), BACT/ALERT® 3D and BIOFIRE® Mycoplasma (results in less than 1 hour) for fast results, ease-of-use and data integrity provided by automated systems.

Rapid quality results not only provide a green light that your biologic or is free of contamination, they can be critical for advanced and cellular therapies with short production cycles and shelf lives. For many patients receiving these therapies, the window of time for treatment has a profound effect on a favorable outcome.

Your solutions:

SCANRDI® (results in 3 hours), BACT/ALERT® 3D and BIOFIRE® Mycoplasma (results in less than 1 hour) for fast results.

By adopting a precise and smart testing process, you will be reducing retests and risks of cross contamination. Our user-friendly platforms will help make your lab workflow more efficient and improve your team’s work environment. Automation reduces risk of human error, removes the subjectivity of test interpretation, increases standardization, simplifies training, and increases data integrity. All of these improvements increase efficiency of each FTE which can reduce reliance on costly outsourcing of testing.

Your solutions:

- BACT/ALERT® 3D is a fully automated and easy-to use identification platform featuring continuous growth monitoring and ready-to-use consumables.

- BIOFIRE® Mycoplasma relies on our PCR-based BIOFIRE® platform: a “lab in a pouch” concept with ready-to-use consumables. It allows testing to be done by anyone, anywhere, anytime. You do not need to equip yourself with a molecular biology laboratory, thus saving costs related to structure and training.

- ENDONEXT™ endotoxin detection test also comes with ready-to-use consumables and brings added value with simple and faster protocols.

You operate in strongly regulated environments. bioMérieux offers a wide range of validation services designed to meet regulatory requirements—from validation guides to comprehensive on-site validation support. So whether you are implementing in-process testing solutions within your laboratory or on your production floor, you can be assured that they uphold the regulatory standards of local and international pharmacopeias.

Your solutions:

- BACT/ALERT® 3D system is described as an alternative method in the pharmacopeia to test the sterility of your products. The system features high and low temperature modules for dual incubation conditions compliant with the different pharmacopoeias.

- SCANRDI® is described in a dedicated drug master file as well as in pharmacopeias as an alternative sterility method.

- both solutions offer 21 CFR Part 11-compliant data management system.

As operational managers, you can confidently progress step-by-step in your process knowing it’s free of contaminants. Our solutions allow you to test for a wide range of contaminants, from different types of samples and with a high sensitivity.

Your solutions:

- SCANRDI® is able to detect bacteria, molds – both in vegetative and sporulated forms – and yeasts. As it is a non-based growth method, stressed and fastidious organisms including those in VBNC state (Viable But Non Culturable) can be detected as well. You can use filterable samples from 1 to 1,000 ml.

- BACT/ALERT® 3D detects a wide variety of microorganisms including bacteria, molds, and yeasts.